Equipment in the phosphate industry must endure extremely severe conditions. Equipment that can meet these conditions is not often found off-the-shelf. Equipment must be simple, durable, and easy to maintain, while delivering superior process performance.

- JPipe Reactor

- SPINDEN Reactor (for MCP/DCP

- KEMWorks Mixing Tee

- Waste-Heat Ammonia Vaporizer

- Cross-Flow Scrubber

- Automated Cleaning Equipment

JPipe reactor

Pipe reactor for MAP and DAP production. The JSA pipe reactor system has the following features:

- Simple design with flexible configuration

- Main reactor pipe achieves high NH3 adsorption

- Easily cleaned by intermittent steam addition

|

|

SPINDEN™ Reactor

The SPINDEN™ has been used in several MCP/DCP Animal Feed plant to increase plant capacity by reducing the recycle ratio.

- Low build up

- Variable product size

- Low Recycle ratio – from 5:1 to 12:1 with a pug mill, compared to 3:1 to 4:1 for the SPINDEN.

- Higher Reaction Efficiency -5% higher conversion of CaCO3 and 0.5-1.0% higher P

- Reduced maintenance and power consumption.

|

|

KEMWorks Mixing Tee

Sulfuric acid and recycle phosphoric acid from the filter must be mixed before added to the reactor. The KEMWorks Mixing Tee does this in a simple but rugged piece of equipment. The mixing tee has a very long life compared with alloy mixing tees and by correct positioning can increase reactor P2O5 efficiency. |

|

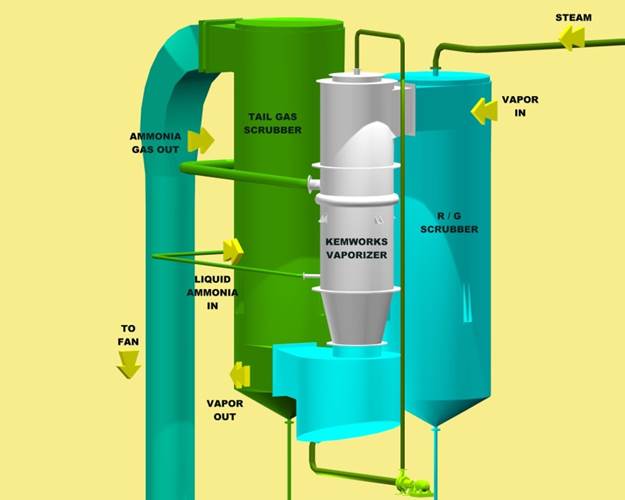

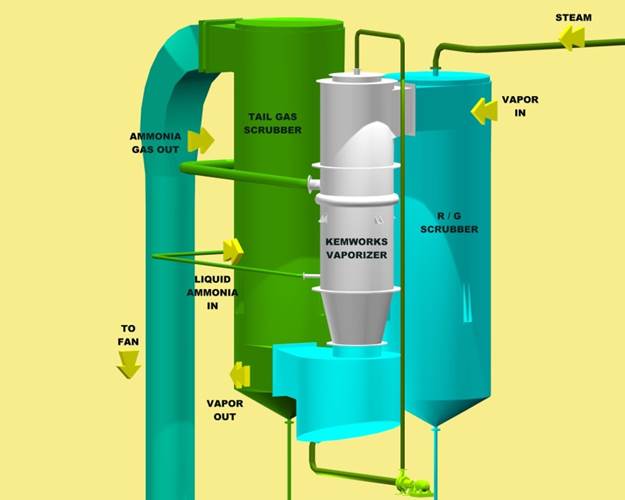

Waste-Heat Ammonia Vaporizer

The increased energy supplied by vapor ammonia evaporates more water from the system so the dryer duty can be reduced and/or the plant can be fed with a lower acid concentration. The heat recovered at the vaporizer is approximately 0.25 MJ / tonne. Taking this duty as steam or natural gas savings translates into approximately $1.50 to $1.80 per tonne, a significant incentive and results in a payback in the order of six months.

Another benefit of adding an ammonia vaporizer in this location is a reduction of emissions. This is due to the scrubbing action of the relatively clean condensate that is recirculated through the plate exchanger to help keep it clean. |

|

KIMRE Cross-Flow Scrubber

A 200,000 m3/h cross-flow scrubber at JR Simplot. Has high scrubbing efficiency, but at the same time resists plugging and is easy to clean. |

|

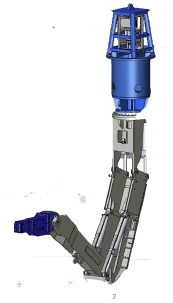

Automated Cleaning Equipment from KT Grant

Acid Tank Machine (ATM)

The ATM-4 is used to clean phosphoric acid plant reactors safely and in a fraction of the time of other methods. It is used by most of the US phosphoric acid producers.

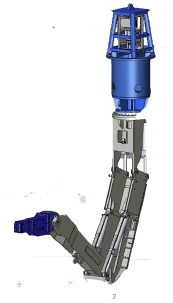

Chute Cleaning Machine (CCM)

The CCM provides a safe way and reliable to clean the chute between the granulator and dryer in a fertilizer plant. |

|